Is Black EPP Foam Better Than Traditional EPE for Aesthetic Consumer Electronics?

The choice of packaging materials plays a pivotal role in the aesthetics and protection of consumer electronics. As companies strive to enhance product presentation while

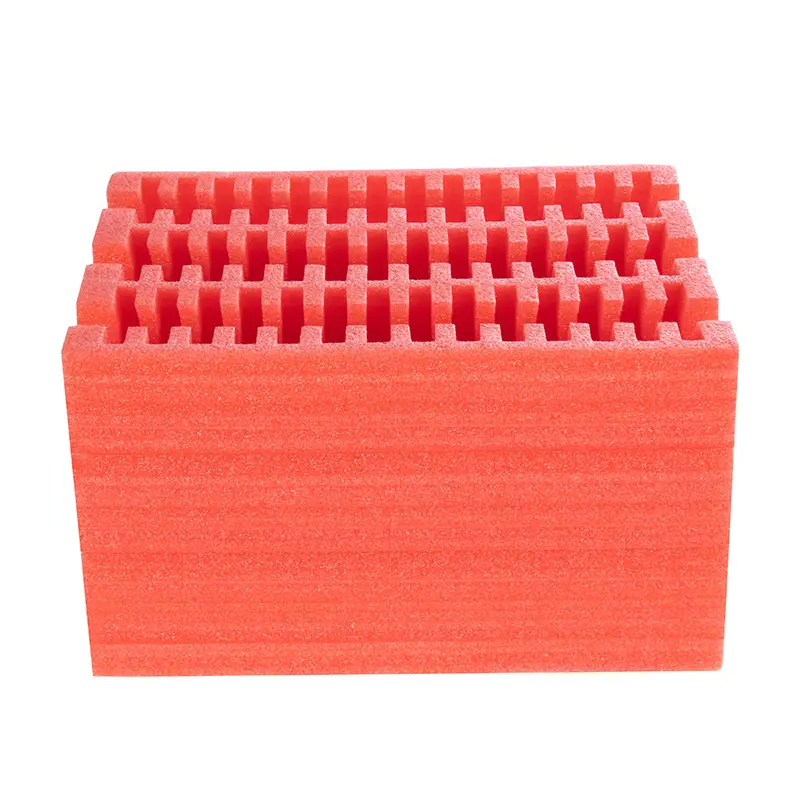

-re0ekjsqlb4ojigkuutt3usg360zqvvu56lxdec0lc.png)