In the world of semiconductor manufacturing and high-tech electronics, the invisible threat of electrostatic discharge (ESD) can be catastrophic. ESD events—often caused by simple friction during handling or shipping—can instantaneously damage sensitive components like microchips, resulting in costly product failure, field returns, and compromised brand reputation. For any business involved in the logistics of these highly sensitive devices, using the right protective packaging is not just a best practice; it is a critical investment in quality assurance. This guide, brought to you by ProFlexPack, a leading foam packaging manufacturer, will explain the critical ESD standards and the precise role of specialized anti-static foam in protecting the semiconductor supply chain.

The Unseen Threat: Understanding Electrostatic Discharge (ESD)

Electrostatic discharge is the sudden flow of electricity between two electrically charged objects. In the semiconductor industry, components are often susceptible to damage at very low voltages (sometimes under 100V), a level far below what a human can feel. This damage can be either catastrophic (immediate, obvious failure) or latent (a weakened component that fails later in the field), making ESD control an absolute requirement. Standard foam materials, being insulative, can actually generate static charges, creating a major risk. This is why every anti-static foam packaging supplier must offer materials specifically engineered to mitigate this danger.

ESD Packaging Standards: Compliance is Non-Negotiable

The global electronics industry relies on stringent standards to certify packaging safety. The most widely recognized standard is ANSI/ESD S20.20, which provides a comprehensive framework for establishing, implementing, and maintaining an ESD control program, including requirements for packaging and handling. Similarly, IEC 61340-5-1 is the primary European equivalent, and both specify that packaging materials must control charge generation and dissipate any existing charge away from sensitive items. Our company ensures all of our relevant products meet the technical requirements of these critical global benchmarks, providing you with a certified, trusted solution from a reliable foam packaging manufacturer.

The Three Types of ESD Foam: Choosing the Right Protection

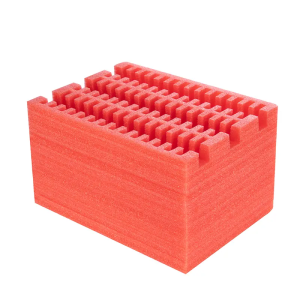

ESD foam is not a monolithic category; it is engineered into three distinct types, each designed for a specific level of protection. Anti-static foam (often pink polyurethane or polyethylene) is treated with additives to minimize the generation of static charge through tribocharging, and it typically has a limited shelf life (around six months). Static Dissipative foam features a much lower surface resistance (10⁶ to 10¹¹ Ω) allowing charges to dissipate gradually and safely. Finally, Conductive foam (often black and carbon-filled, with a surface resistance of 10³ to 10⁵ Ω) offers the fastest path to ground, often used to create a “Faraday cage” effect when components are fully enclosed. As a leading anti-static foam packaging supplier, ProFlexPack offers all three variants—including permanent anti-static options—customized to the required component sensitivity.

Implementation in Semiconductor Logistics

For semiconductor logistics, the application of anti-static foam packaging supplier products is multi-faceted. The foam is used as custom inserts inside transport cases, trays, and shipping boxes. These inserts must be precisely CNC-cut or molded to the contour of the sensitive devices, preventing movement and ensuring the ESD-safe material is the only thing contacting the device pins or surfaces. Utilizing our high-density anti-static foam ensures that components maintain their electrical integrity whether they are being shipped across the globe, stored in a warehouse, or moved between assembly stations in an ESD Protected Area (EPA). Our product designs focus on achieving maximum physical security while adhering to strict electrical specifications.

ProFlexPack’s Advanced Anti-Static Materials and Specifications

At ProFlexPack, our anti-static product line includes high-performance materials like Anti-Static EPE (Expanded Polyethylene) and Anti-Static EPP (Expanded Polypropylene) inserts. The EPE material is commonly pink and offers excellent cushioning combined with reliable static dissipation (e.g., surface resistivity of 10⁸ to 10¹¹ Ω). For high-value, reusable applications like semiconductor test trays or aerospace electronics, our EPP Anti-Static Inserts combine the superior mechanical protection of EPP (multi-impact resilience) with permanent anti-static properties. We use materials and custom formulations engineered to provide both physical shock absorption and precise electrostatic control throughout the entire transit and storage cycle.

Choosing the Right Foam Packaging Manufacturer Partner

The complexity of ESD control demands a partner with deep technical knowledge. Choosing a capable foam packaging manufacturer that understands both the physics of shock absorption and the intricacies of static electricity is paramount to protecting your product and reputation. ProFlexPack not only supplies the specialized foam materials but acts as a comprehensive packaging solutions provider, offering design expertise to integrate the foam seamlessly into your existing workflow and outer packaging. Our team of ESD specialists holds industry-recognized certifications and stays ahead of evolving static control standards, ensuring every solution is rigorously tested for performance and compliance. We are committed to supplying high-quality, fully compliant anti-static foam packaging solutions that deliver peace of mind and measurable cost savings by virtually eliminating ESD-related damage, while providing ongoing technical support to adapt to your changing product or supply chain needs.

-re0ekjsqlb4ojigkuutt3usg360zqvvu56lxdec0lc.png)