Transporting high-value equipment—be it sensitive medical devices, complex machinery, or sophisticated consumer electronics—across long distances introduces a high degree of risk. The logistical challenge involves protecting goods against severe, single-event impacts during handling, managing variable environmental conditions over weeks, and minimizing transit weight to control costs. Expanded Polystyrene, or EPS packaging foam, is a proven solution that addresses all these concerns simultaneously. Its unique physical properties make it critical for securing cargo in the international supply chain. Our company, ProFlexPack, engineers customized eps foam solutions designed for these demanding long-haul applications.

EPS Foam’s Single-Impact Superiority for Handling Drops

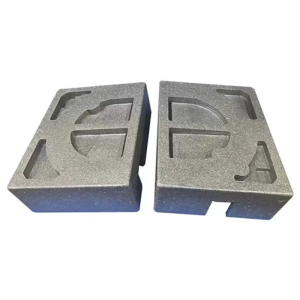

For high-value equipment, the greatest risk often occurs during abrupt handling events, such as accidental drops from a forklift or loading dock. EPS foam is characterized by its remarkable ability to absorb high-impact energy in a single event. Composed of approximately 98% air trapped within a closed-cell structure, the foam is designed to crush incrementally upon impact, effectively dissipating the shock away from the product. Our manufacturing process allows us to mold custom eps foam end-caps and rails that precisely fit the equipment’s geometry, concentrating the material where impact protection is most needed to achieve optimal cushioning for fragile and heavy goods. This targeted design ensures that critical components—such as sensitive sensors or precision mechanical parts—remain shielded from catastrophic damage during unforeseen drops. Unlike rigid alternatives that transfer impact force directly, EPS’s controlled crushing action provides a buffer that preserves equipment integrity, minimizing costly repairs or replacements after transit.

Guaranteed Dimensional Stability Across Environmental Extremes

Long-distance transport means exposure to a vast range of temperatures and humidity levels, from freezing container yards to hot, humid warehouses. These environmental extremes can compromise less resilient packaging, causing deformation or failure. A critical specification of eps packaging foam is its exceptional dimensional stability. Its physical properties are proven to remain virtually unaffected across its service temperature range (often-17℃ to 43℃). This means that over weeks of transit, the foam maintains its precise molded shape and cushioning characteristics, ensuring the high-value equipment remains snugly secured inside the carton without loosening or shifting. Unlike materials that shrink, expand, or warp under environmental stress, EPS retains its structural integrity to prevent gaps that could lead to movement-related damage. This reliability ensures consistent protection from origin to destination, even when navigating unpredictable climate fluctuations in global logistics.

Cost-Effectiveness and Reduced Freight Weight with EPS Packaging Foam

In a cost-sensitive global supply chain, packaging weight directly correlates with freight expenses. The high air content of EPS foam makes it one of the lightest protective materials available, providing excellent cushioning at a minimal mass. By choosing custom EPS packaging foam over heavier, less efficient protective materials, businesses can achieve significant, cumulative savings in shipping costs over long distances. This lightweight characteristic enhances manual handling safety and contributes to a lower overall carbon footprint for international operations, providing both financial and environmental benefits. Its low density also optimizes pallet and container load capacity, allowing more units to be shipped per trip—further driving down per-unit logistics costs. Unlike bulky alternatives that inflate shipping budgets, EPS balances cost efficiency with uncompromised protection, making it a pragmatic choice for high-volume or long-haul shipments.

Thermal Insulation for Temperature-Sensitive Cargo

Many high-value products, including diagnostic kits, pharmaceuticals, and certain electronic components, are sensitive to temperature fluctuations and require stability during long transit times. The closed-cell composition of EPS foam gives it exceptional thermal insulation properties, making it an ideal choice for cold chain or controlled-temperature logistics. It acts as an effective thermal barrier, slowing down heat transfer and helping to maintain a stable internal temperature range. This insulating capability is indispensable for ensuring product integrity when items are shipped across diverse climate zones and helps mitigate the risk of condensation damage. Unlike porous materials that offer minimal thermal protection, EPS foam’s dense closed-cell structure locks in temperature consistency, safeguarding temperature-sensitive goods from spoilage or performance degradation. This reliability supports compliance with industry-specific cold chain standards, ensuring products reach their destination in optimal condition while reducing costly losses from temperature-related failures.

Specialized Anti-Static Protection by ProFlexPack

For electronics manufacturers shipping sensitive components like circuit boards and sensors, physical protection must be paired with electrostatic discharge (ESD) safety. Understanding this industry-specific requirement, ProFlexPack provides specialized Anti-Static EPS Foam Pads. These pads are chemically treated to safely dissipate static charges that can accumulate during handling and transit, preventing invisible but catastrophic damage to micro-components. By partnering with ProFlexPack, you secure a solution that guarantees your high-value electronic equipment receives both superior impact protection and essential ESD compliance, ensuring safe arrival anywhere in the world. Unlike standard EPS foam that offers no static control, our anti-static variant maintains consistent charge-dissipating performance across transit conditions. This dual-layer defense aligns with strict industry standards and eliminates latent ESD risks, preserving component functionality and avoiding costly field failures or product recalls.

-re0ekjsqlb4ojigkuutt3usg360zqvvu56lxdec0lc.png)