When it comes to shipping sensitive electronics, protecting them from physical damage and static discharge is of paramount importance. Components like integrated circuits (ICs), printed circuit boards (PCBs), and optical sensors require specialized packaging solutions that can shield them from both mechanical shocks and electrostatic discharge (ESD). In this guide, we will explore two of the most popular packaging options—anti-static foam and airbag solutions—to help you make the best decision for safeguarding your sensitive electronic products.

As an anti-static foam packaging supplier, ProFlexPack offers customizable packaging solutions designed to protect your electronics throughout the shipping process. Let’s dive into how these two packaging methods compare and why anti-static foam is often the preferred choice for sensitive electronics.

What Is Anti-Static Foam Packaging?

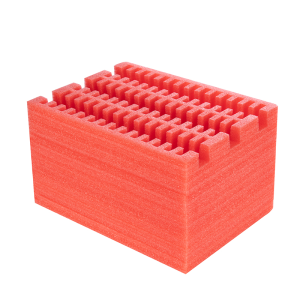

Anti-static foam is a specially designed foam material made from expanded polyethylene (EPE), engineered to protect electronic components from the harmful effects of static electricity. Unlike regular foam, anti-static foam is treated with anti-static agents that prevent the buildup and discharge of static electricity. This makes it an ideal solution for protecting sensitive electronics like ICs, PCBs, and camera modules during transport. The foam’s unique structure provides a cushioning effect that absorbs shock and vibration, minimizing the risk of physical damage to delicate components. Additionally, the anti-static surface treatment ensures that your products remain safe from electrostatic discharge (ESD), which can cause permanent damage to sensitive circuits.

Advantages of Anti-Static Foam Packaging

Dual Protection for Sensitive Components: Anti-static foam provides both physical shock absorption and static protection. This dual-layer of defense is critical for components such as ICs and optical modules, where electrostatic discharge can cause irreversible damage. Anti-static foam not only protects from physical impact but also ensures that no static discharge occurs during transport.

Customizable Designs for Every Need: At ProFlexPack, we understand that one size does not fit all. As an anti-static foam packaging supplier, we offer custom designs that cater to the specific dimensions, shapes, and weight of your products. Whether you need molded foam inserts or surface coatings, we can tailor our solutions to meet your requirements.

Consistent Static Protection: Every batch of anti-static foam we produce undergoes rigorous testing to ensure it consistently provides the same level of static protection. This guarantees that every electronic component is safeguarded against static discharge, no matter the production run.

- Clean and Dust-Free: The smooth, dust-free surface of anti-static foam ensures that your PCBs, camera modules, and other sensitive components remain free from contaminants during shipping. This is crucial for maintaining product integrity and ensuring that your products arrive in pristine condition.

Airbag Packaging: Another Option

While airbag packaging is an effective solution for cushioning products from physical impacts, it does not provide any static protection. Airbag packaging involves inflatable air cushions that surround the product, offering a protective barrier against shocks and drops. It’s often used for larger, more durable products that are less sensitive to static. While airbag solutions are great for protecting larger, robust items, they fall short when it comes to safeguarding static-sensitive electronics. For example, ICs, PCBs, and other fine electronics are susceptible to electrostatic discharge (ESD), which can cause malfunction or failure. Airbags do not offer any protection against ESD, making them less suitable for sensitive components.

Benefits and Limitations of Airbag Packaging

Effective Shock Absorption: Airbags are great at protecting larger items from impact during shipping. Their inflatable nature helps to cushion products from drops or rough handling, making them ideal for more durable items.

Cost-Effective for Bulkier Items: Airbag packaging is often cheaper compared to other protective solutions, especially when shipping larger products. Their lightweight nature also reduces shipping costs, making them an attractive option for companies focused on reducing transportation expenses.

Lack of Static Protection: Unlike anti-static foam, airbag packaging does not protect against electrostatic discharge. For sensitive electronics like PCBs and ICs, static buildup can result in permanent damage, making airbag packaging unsuitable for these types of products.

Not Ideal for Small, Static-Sensitive Products: While airbag packaging works well for large, durable items, it’s not suitable for small, delicate electronics that require static protection. Airbags are not effective in preventing the risk of ESD, leaving sensitive electronics vulnerable during shipping.

How to Choose the Right Packaging Solution?

The decision between anti-static foam and airbag packaging depends on the nature of the products you are shipping. If you are transporting static-sensitive electronics like ICs, PCBs, or optical components, anti-static foam is the best choice. It offers comprehensive protection against both physical damage and static discharge, ensuring your products arrive safe and functional. For larger, more durable products that are not sensitive to static, airbag packaging may be a more cost-effective solution. However, for small, precision electronics, ProFlexPack’s anti-static foam packaging provides the most reliable and protective option.

ProFlexPack’s Commitment to Quality and Customization

At ProFlexPack, we specialize in providing high-quality, customizable packaging solutions for sensitive electronics. As a trusted foam packaging manufacturer, we understand the unique needs of your products and offer tailored solutions that ensure they are protected from both physical damage and static discharge. Our expertise in anti-static foam packaging allows us to provide the best possible protection for your electronic components during transport.

-re0ekjsqlb4ojigkuutt3usg360zqvvu56lxdec0lc.png)