When transporting and handling sensitive electronic components, static electricity (ESD) poses a significant risk. Even the smallest electrostatic discharge can severely damage or destroy electronic devices, resulting in costly repairs, returns, and damaged reputations. Yet many procurement managers still remain uncertain about the role of foam packaging solutions in protecting these fragile components. In this article, we’ll debunk common myths surrounding ESD foam packaging and explain why choosing the right foam packaging solutions is essential for the safe transportation of your sensitive electronics.

What is ESD Foam Packaging and Why Does it Matter?

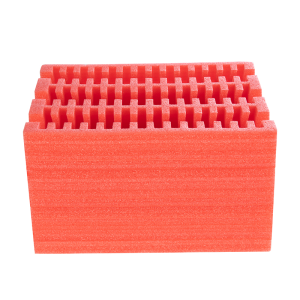

ESD foam packaging is specifically designed to protect sensitive electronic devices from the harmful effects of electrostatic discharge. This type of foam packaging uses materials with controlled resistance levels, typically ranging from 10⁷–10¹⁰Ω, to ensure that electronic components, such as semiconductors and ICs, remain safe during transportation, assembly, and storage. ProFlexPack provides ESD foam packaging solutions that ensure stable electrostatic properties across production batches. Unlike lower-quality foams, which may exhibit fluctuations in resistance, ProFlexPack foam solutions maintain consistent protection, safeguarding your products from static damage during every stage of the supply chain. Without proper ESD protection, the risk of damage during shipping, assembly, or storage increases significantly. Using foam packaging solutions that incorporate ESD protection acts as a barrier, preventing damage to your electronics throughout their journey.

Myth 1: All ESD Foam Packaging is the Same

A common misconception is that all ESD foam packaging offers the same level of protection. In reality, not all foam is created equal. Some foams may only provide basic static protection, but their resistance levels can vary, compromising the safety of your products. At ProFlexPack, we take pride in ensuring the consistent electrostatic performance of our ESD foam packaging. Each batch is rigorously tested to meet strict quality standards, ensuring that our foam solutions deliver reliable protection for your sensitive electronics. By using substandard foam packaging, you risk exposing your components to potential ESD damage.

Myth 2: ESD Foam Packaging is Only for Small Components

Another widespread misconception is that ESD foam packaging is only effective for small, delicate components, like microchips or integrated circuits. However, ProFlexPack’s foam packaging solutions are designed to protect a wide variety of electronic devices, including larger and more complex products, such as smartphones, medical equipment, and industrial instruments. Our custom-designed ESD foam packaging solutions offer flexible protection for both small and large items. No matter the size or complexity of your electronics, ProFlexPack can provide tailored protection, ensuring that even large or intricate devices receive the appropriate safeguards during transport.

Myth 3: ESD Foam Packaging Can Contaminate Products

There’s a concern that foam packaging may leave behind dust or residues that could contaminate sensitive electronic components. However, high-quality ESD foam—such as the one we offer at ProFlexPack—is clean, dust-free, and non-abrasive. Our ESD foam solutions are specifically engineered to prevent contamination, making them ideal for use with products like PCBs, optical modules, and medical electronics. By using ProFlexPack foam packaging, you ensure that your products remain clean and free from any harmful debris, maintaining the integrity of your sensitive components.

Myth 4: ESD Foam Packaging is Expensive and Unnecessary

Many procurement managers avoid using ESD foam packaging because they believe it’s an unnecessary expense. While cheaper packaging options may seem cost-effective upfront, the long-term savings provided by ESD foam packaging solutions far outweigh the initial price difference. Using low-cost, non-ESD packaging may result in hidden static damage to your products, leading to costly repairs or returns. Since ESD damage is often invisible until the product is in use, it can cause significant issues that would otherwise be avoided with the proper protective packaging. At ProFlexPack, we provide cost-effective foam packaging solutions that protect your electronics and help you avoid the long-term financial impact of static damage.

Myth 5: All ESD Foam Packaging Works in Any Environment

Not all ESD foam packaging is suitable for every environment. Different environments require different levels of protection, depending on the static risks involved. For instance, packaging used in clean rooms or sensitive production environments must meet specific cleanliness standards to avoid contamination. ProFlexPack understands that a one-size-fits-all approach doesn’t work for every application. We offer customized foam packaging solutions that are designed to meet the unique needs of your operating environment, whether that be in a clean room, high-humidity environment, or industrial setting. Our ESD foam packaging solutions can also integrate seamlessly with other anti-static systems such as conductive trays, shielded bags, and cleanroom materials, providing comprehensive protection throughout the process.

Conclusion: The Importance of Choosing the Right ESD Foam Packaging

When it comes to safeguarding sensitive electronics, ESD foam packaging is an essential part of the overall packaging strategy. However, choosing the right foam packaging solutions is crucial. By debunking these common myths and understanding the real value of ESD foam packaging, procurement managers can make more informed decisions that will better protect their products, reduce costs, and increase customer satisfaction. At ProFlexPack, we specialize in delivering high-quality foam packaging solutions tailored to the unique needs of your business. Our ESD foam packaging is rigorously tested to ensure its reliability and is available in a range of sizes and configurations, ensuring that your electronic products are protected during transport.

-re0ekjsqlb4ojigkuutt3usg360zqvvu56lxdec0lc.png)